Make-Up Air units are becoming requirements in all commercial kitchen spaces for their exhaust hood system. The exhaust hood system works by removing dirty air from inside the kitchen space, and expelling it outdoors. A make-up air unit then comes into play by taking air from outside the building and inserting it into the kitchen space, essentially replacing the dirty air with clean air from outside. By incorporating a direct-drive motor in your make-up air unit you can increase performance, overall energy consumption, and reduce maintenance.

What is a direct-drive fan? There are two basic types of exhaust fans - belt-driven and direct drive. Belt-driven is pretty self explanatory - it utilizes a belt to turn the fan blades. Direct-drive exhaust fans removes the belt from the equation and instead connects the motor and the fan assembly. By removing the belt you increase the overall efficiency of the make-up air fan while also making the fan easier to maintain and clean overall. Not only are you saving money in terms of energy consumption by moving to a direct-drive exhaust fan, but by making it easier to maintain and clean the exhaust fan you will save money in the long run with repairs and maintenance costs.

Direct-drive fans also allow you to incorporate an Electronically Commutated Motor (ECM), allowing flexibility in terms of fan speed and other variables to allow for your exhaust hood system to run as efficiently as possible. ECMs can be set up to automatically adjust the fan rates based on cooking loads, and this ability has been shown to save upwards of 88% in energy consumption when set up correctly.

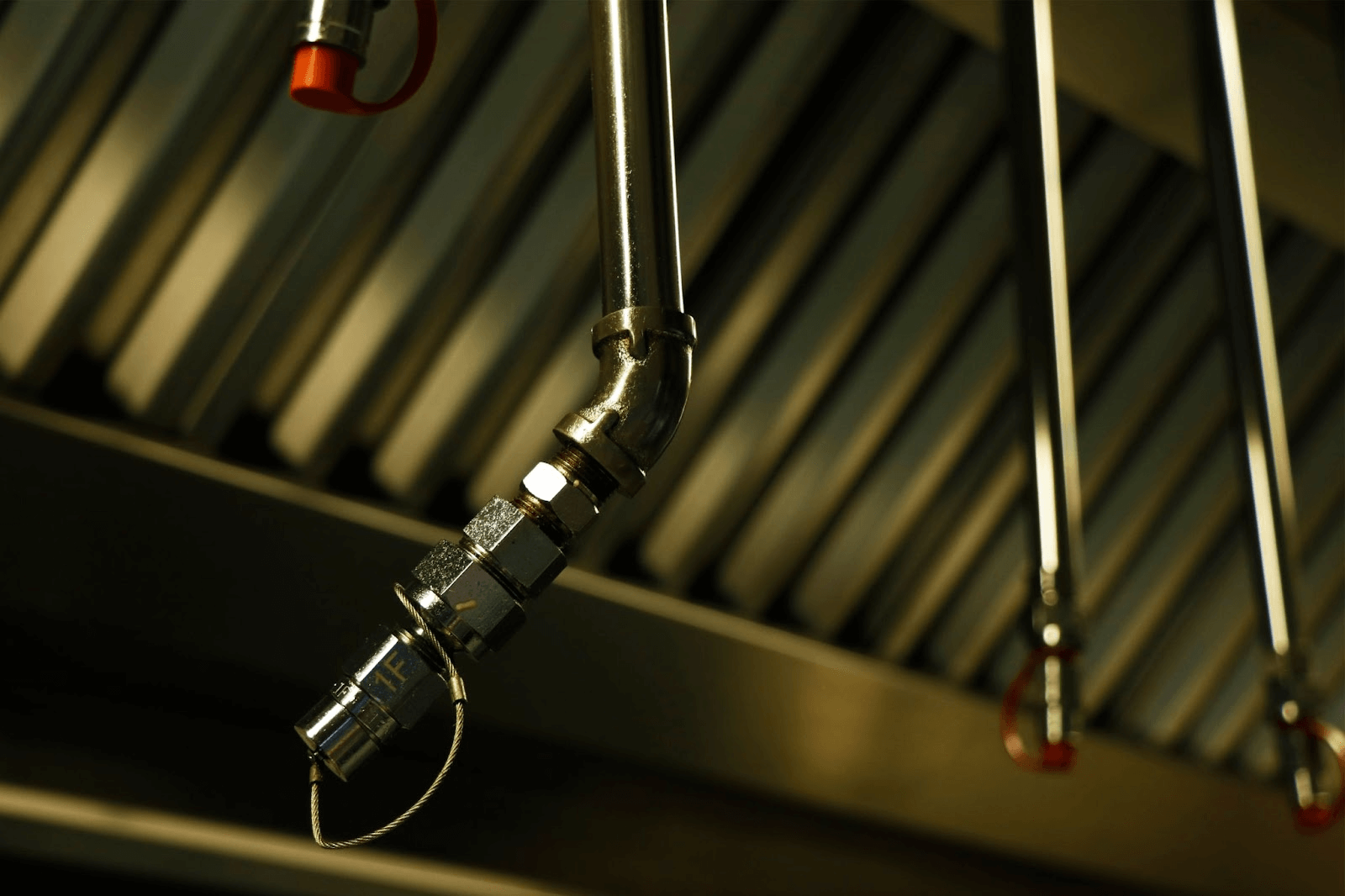

By removing the belt, bearings, and pulleys that are used in Belt-Drive make-up air units you remove the need for regular part replacements and maintenance, as well as more intensive cleaning to keep the make-up units running. Direct-drive units are easier to maintain and operate, have increased life-spans over belt-driven units, and when utilized with a proper ECM set up can greatly reduce energy consumption over the longevity of operation. Exhaust hood systems are essential to any commercial kitchen space to remove airborne particles that can contaminate kitchen surfaces as well as pollute the air quality of the kitchen. There are many components that come into play in your exhaust hood set up - you have your blower motor, exhaust fan, grease traps, ductwork, etc. To fully understand how each and every part of the exhaust hood works can be overwhelming and daunting, however understanding these components not only helps when it comes to troubleshooting what may be wrong if your exhaust hood is acting up, but also allows you to better grasp how everything is working to best optimize your exhaust hood system for you kitchen space.

Exhaust fans may seem pretty simple in appearance, however they are complex and have many components that help to ensure they work as efficiently as possible. One of these components are the louvers - the horizontal slats that cover the input area of the fan. The purpose of the louvers is not just cosmetics - the angle and other variables of the louvers help create an optimized air flow while protecting the fan from excess debris. The louvers are designed using a series of criteria:

1) Free Area - the free area of the louver is what allows air to freely pass between the openings. Free area is determined by taking the total louver face area, and subtracting the airflow restrictions a la the blades and fans. The purpose of free area is to prevent excess debris from making its way through the opening while allowing as much air to pass through. Too much free area prevents the louver from rejecting water, and too little free area can cause sub-optimal airflow due to air flow restrictions.

CUSTOM FABRICATOR

CUSTOM FABRICATOR