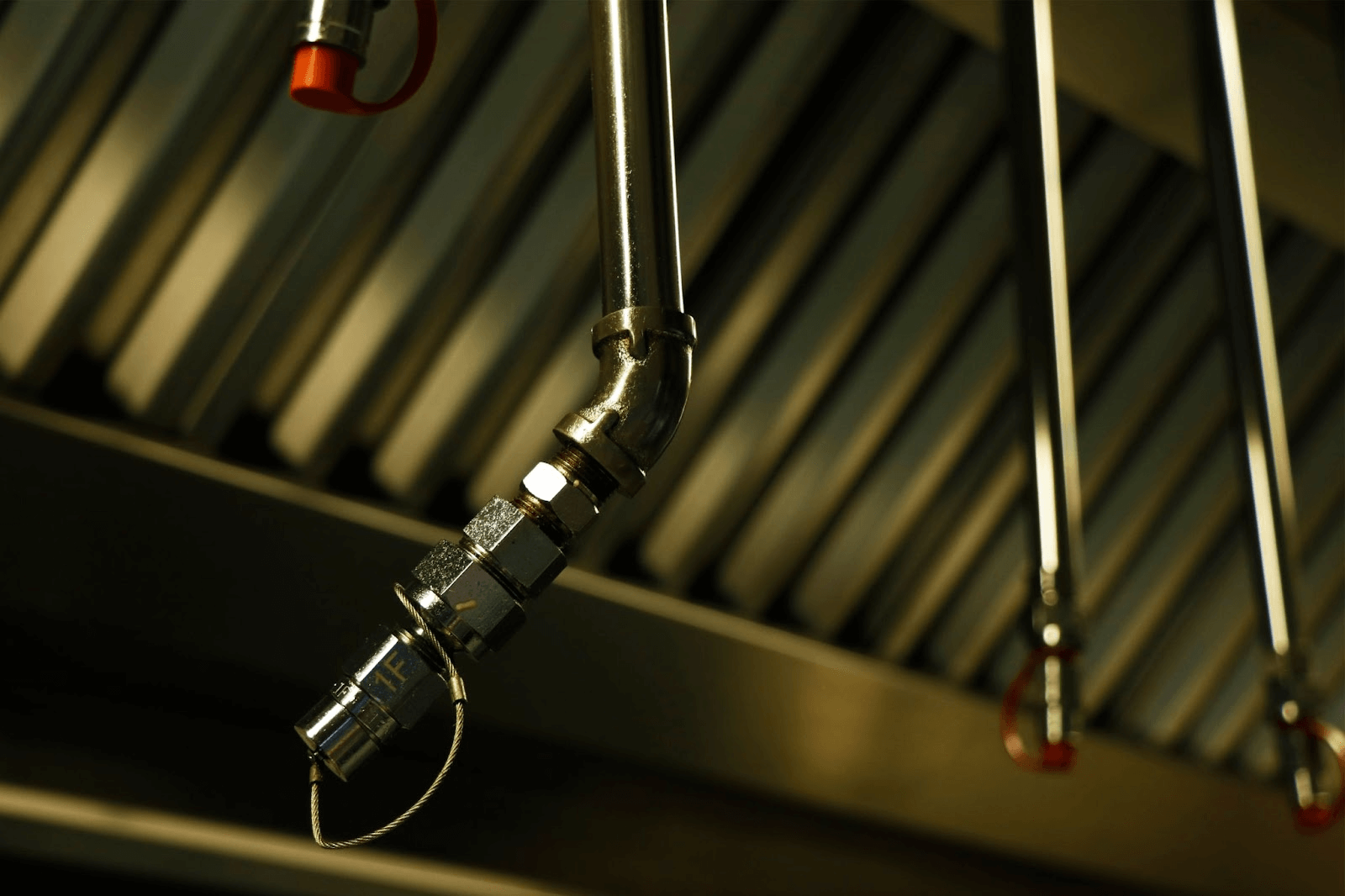

Exhaust hood systems are essential to any commercial kitchen space to remove airborne particles that can contaminate kitchen surfaces as well as pollute the air quality of the kitchen. There are many components that come into play in your exhaust hood set up - you have your blower motor, exhaust fan, grease traps, ductwork, etc. To fully understand how each and every part of the exhaust hood works can be overwhelming and daunting, however understanding these components not only helps when it comes to troubleshooting what may be wrong if your exhaust hood is acting up, but also allows you to better grasp how everything is working to best optimize your exhaust hood system for you kitchen space.

Exhaust fans may seem pretty simple in appearance, however they are complex and have many components that help to ensure they work as efficiently as possible. One of these components are the louvers - the horizontal slats that cover the input area of the fan. The purpose of the louvers is not just cosmetics - the angle and other variables of the louvers help create an optimized air flow while protecting the fan from excess debris. The louvers are designed using a series of criteria:

1) Free Area - the free area of the louver is what allows air to freely pass between the openings. Free area is determined by taking the total louver face area, and subtracting the airflow restrictions a la the blades and fans. The purpose of free area is to prevent excess debris from making its way through the opening while allowing as much air to pass through. Too much free area prevents the louver from rejecting water, and too little free area can cause sub-optimal airflow due to air flow restrictions.

2) Water Penetration - louvers are designed to keep out excess debris from passing through, and this include water as well. To help keep out water the louvers should be designed around the beginning point of water penetration, which is defined as the moment at which 0.01 fluid oz of water will penetrate the louver. By designing the louvers based on blade profiles, and a combination of blade spacing and blade position you can efficiently keep out water.

3) Air Volume Flow Rate - exhaust hood systems are designed to remove dirty air from an area, and replace it with clean air. Air Volume Flow Rate is defined as the measurement of air flow in or out of a space, and is measured in cubic feet per minute, or CFM. Louvers can be designed to help the exhaust hood system achieve the required CFM per square foot to ensure that the exhaust system is running optimally.

By utilizing a properly designed louver for your commercial kitchen space can dramatically improve the effectiveness of your exhaust hood system. A louver that is set up for optimal free area, water penetration, and air volume CFM can make a significant difference in the air quality of your kitchen space. If you are still confused, or have any questions, HoodMart specialists are available to help answer any questions you may have and to guide you through the process of purchasing the perfect exhaust hood system for your restaurant or commercial cooking space. HoodMart provides our customers with a wide range of exhaust hood systems - from Compensating (Short Cycle) to Perforated Supply Plenum PSP - as well as all exhaust hood accessories such as no weld Grease Duct, hood filters, canopy hood lights, and curbs. Our walk-in selection offers coolers and freezers from quick ship to custom. If you have questions regarding the purchase of your hood system or walk-in, please feel free to contact one of our experts today by calling us at 1.855.411.6386 or by contacting us through our live chat system.

CUSTOM FABRICATOR

CUSTOM FABRICATOR