Whether you’re running a commercial kitchen space or a food truck, you likely are running an exhaust hood system of some type. Just like any other piece of equipment or appliance you may need to inspect every once in awhile to make sure everything is looking good to go and running efficiently. Regular cleaning and maintenance will help keep your equipment and your kitchen up and operational with little to no downtime, and here are some tips to look out for when you are inspecting your kitchen exhaust system.

If your kitchen is cooking with grease, fats, and oils you should be running a Type 1 Exhaust Hood system. These units are specifically designed for the smoke, vapor, and grease and use filters to help clean the air before it goes to the upblast fans and removed from the building. With these type of units you need to regularly check for oil and grease build ups as there are health risks involved with the build ups as well as the potential for grease fires. Regularly cleaning surface materials, and proper filter cleaning and replacement should take care of this on the short term. If you are starting to notice an unusually high amount of grease build up then you should consider calling a hood cleaning service to come in and clean the entire system to avoid any further damage or fire risks.

Type 2 Exhaust Hood Systems can be found over kitchen appliances that do not use many oils or greases. These specific type of hood systems are used to pull out heat, moisture and condensation, and odors from a kitchen space. Since they are not dealing with airborne elements such as grease they do not require a filter, and they do not require regular cleaning like with a Type 1 unit. However just like a Type 1 unit you have moving parts and components, so check regularly for any signs of wear and tear that may require replacement of parts. Also check for any weird noises that may be coming from the equipment. In the event that something appears or sounds off you should contact a local certified technician to come in and evaluate the situation.

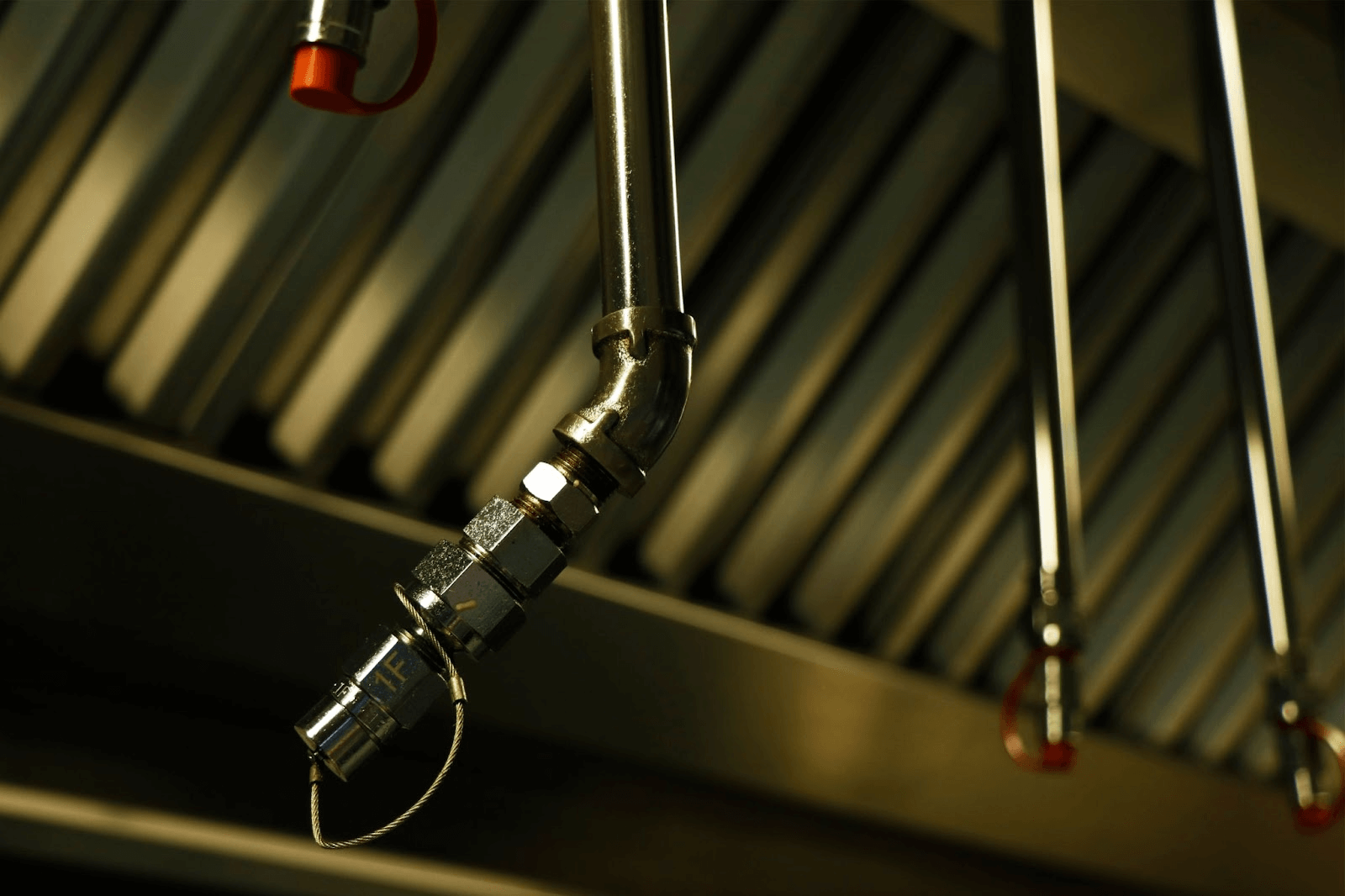

Many kitchens are required to install a fire suppression system to stop any fires that may accidentally occur. When checking a fire suppression system you should check first for the cleanliness of the system. If it seems dirty a simple wipe down can work wonder. Next you need to check the positioning of the nozzles as these should be positioned and located at the plenum or duct opening of the unit. Make sure the nozzles are accessible and that there’s nothing blocking or in the way, and inspect the protective caps on the nozzles for any damage and replace if necessary. Review the piping and tubing for any signs of wear or damage, and schedule a tech to replace any parts or piping / tubing that doesn’t look up to par.

The exhaust hood system and the fire suppression system are the two main components to look out for in your kitchen set up. Reviewing and inspecting these components - along with regular maintenance and cleaning - should keep them up and running for years with little to no downtime. When in doubt you can always reach out to local certified technicians who can come out and review everything for you to make sure you are up to code and safe.

HoodMart provides our customers with a wide range of exhaust hood systems - from Compensating (Short Cycle) to Perforated Supply Plenum PSP - as well as all exhaust hood accessories such as no weld Grease Duct, hood filters, canopy hood lights, and curbs. If you still have questions regarding the purchase of your hood system, please feel free to contact one of our experts today by calling us at 1.800.715.1014 or by contacting us through our live chat system.

CUSTOM FABRICATOR

CUSTOM FABRICATOR