Alright, picture this: you're in the heart of a bustling kitchen, and the sizzle of grills fills the air. Now, imagine you're the one responsible for keeping that kitchen running smoothly. The secret sauce? It's all about having the right ventilation hood. The correct type of hood is crucial for creating a safe and efficient cooking environment, helping to manage smoke, grease-laden vapors, and heat effectively. Don't worry, though, the experts at HoodMart have your back. With our lineup of Type 1 and Type 2 hoods, we'll guide you through understanding which to use and when, ensuring your kitchen stays compliant and operates at its best.

Type 1 Hoods: Tackling Grease-Laden Environments

Type 1 hoods, often referred to as grease hoods, are purpose-built for kitchens where cooking processes generate substantial grease and smoke. These hoods are strategically positioned above equipment like fryers, griddles, and ranges to capture and expel grease-laden vapors, ensuring a cleaner and safer kitchen atmosphere.

Key Attributes of Type 1 Hoods:

Grease Filtration: Equipped with specialized grease filters, Type 1 hoods efficiently trap grease-laden vapors Regular maintenance of these filters is essential to uphold their effectiveness.

Make-Up Air Supply: Type 1 hoods often incorporate a make-up air supply mechanism, balancing airflow by replacing exhausted air with fresh air. This feature contributes to maintaining optimal air quality and ventilation efficiency.

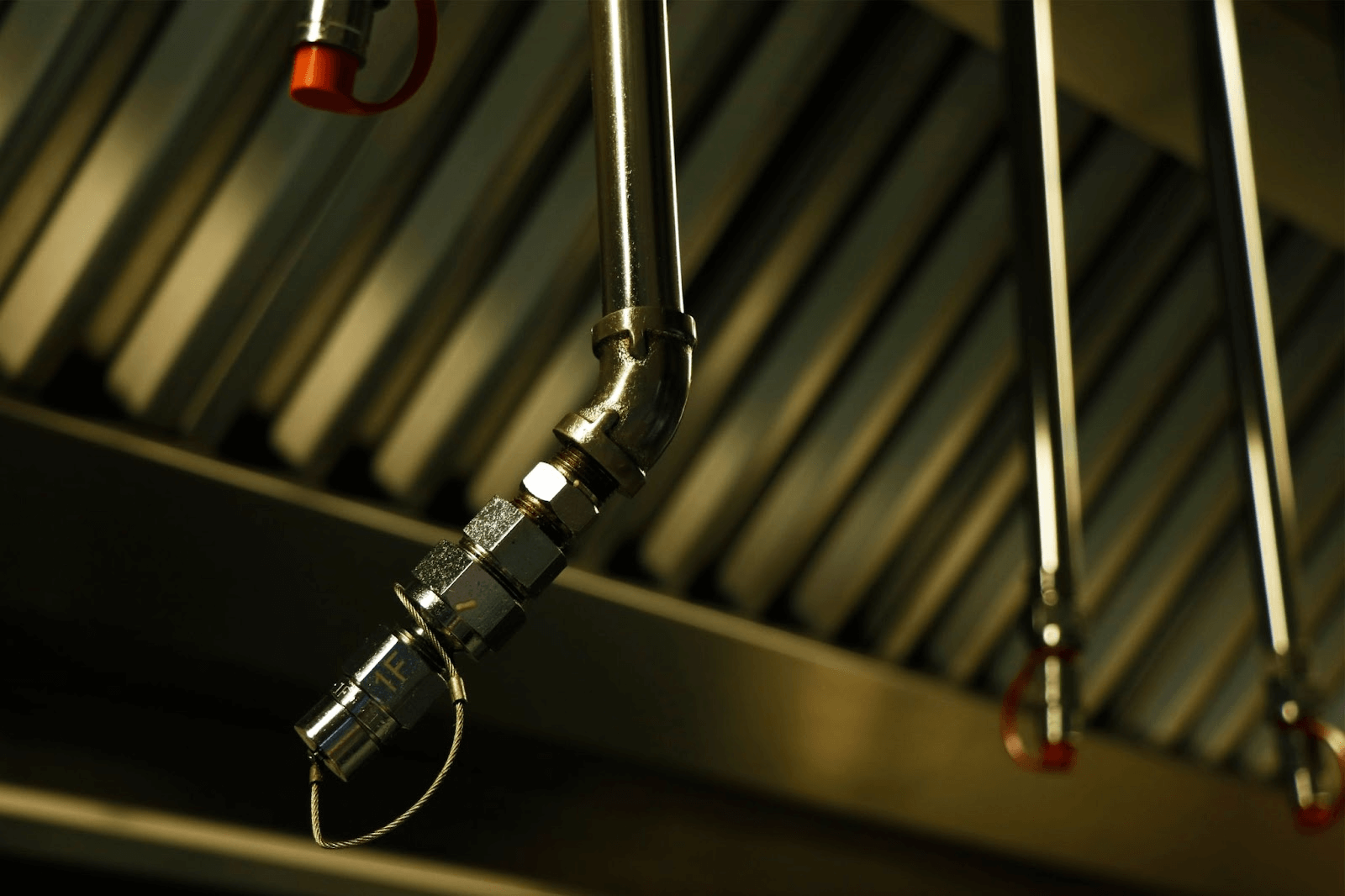

Fire Suppression Integration: Recognizing the heightened fire risk in grease-laden environments, Type 1 hoods seamlessly integrate with fire suppression systems. These systems swiftly detect and extinguish grease fires, bolstering safety measures in the kitchen.

Type 2 Hoods: Addressing Heat and Moisture Challenges

Type 2 hoods, also known as condensate steam hoods, cater to kitchens where cooking appliances produce heat, steam, and moisture rather than heavy grease. These hoods are instrumental in removing heat, steam, and odors from the kitchen environment, ensuring a comfortable and conducive workspace.

Key Features of Type 2 Hoods:

Steam, Heat, and Moisture Management: Engineered to capture and expel steam, moisture, and heat generated by cooking equipment, Type 2 hoods utilize exhaust fans and ductwork to ventilate the kitchen effectively. This facilitates a cooler and more pleasant environment for kitchen staff.

Supply Air Integration: If supply air is required, HoodMart provides options for introducing it through an internal (short cycle) make-up air chamber, perforated supply plenum (PSP), or ceiling diffusers, ensuring proper ventilation and air circulation.

Expert Guidance is Essential When Selecting A Hood Type for Your Restaurant

Understanding the distinctions between Type 1 and Type 2 hoods is crucial for ensuring your kitchen operates efficiently and safely. Whether you're dealing with grease-laden vapors from frying and grilling or managing heat and steam from boiling and baking, selecting the right hood type is key to maintaining a clean and compliant kitchen environment. HoodMart offers a wide range of high-quality hoods to meet every requirement, ensuring your kitchen stays up to code and functions smoothly.

Why Proper Installation and Maintenance Matter

The efficacy and safety of your kitchen hoods depend on proper installation, routine maintenance, and adherence to local regulations. Ensuring your hoods are correctly installed and regularly maintained will help prevent costly repairs and ensure a safe working environment for your staff. For expert guidance in selecting the ideal hood for your kitchen, reach out to the knowledgeable team at HoodMart. We're here to help you find the best ventilation solutions for your restaurant's unique needs - we can even recommend an installer for your project. So if you’re ready to get started, we’re ready to help. Contact us today!

CUSTOM FABRICATOR

CUSTOM FABRICATOR