We use cookies to help improve our services, make personal offers, and enhance your experience. If you do not accept optional cookies below, your experience may be affected. If you want to know more, please read the Learn more.

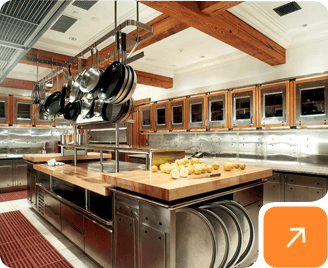

Why Makeup Air Is Important

4 problems you can solve with a makeup air unit for your kitchen:

POORLY PERFORMING KITCHEN EXHAUST HOODS

Without a makeup air unit for your kitchen, your exhaust hoods don’t do their job as well. That’s because the lack of supply air causes an increase in static pressure that lowers the cubic feet per minute (CFM) of air the equipment can remove from your kitchen.

EXCESS KITCHEN GREASE

When your exhaust hood doesn’t work well, you’ll notice more grease building up on the surfaces of your kitchen and your staff will have to spend more time cleaning.

AIR QUALITY CONCERNS

Air quality can’t be taken lightly because it affects the health and safety of your employees. The smoke and VOCs (volatile organic compounds) given off by cooking can cause air quality concerns in your kitchen. Prolonged exposure to these substances can lead to respiratory problems. The last thing you need is your kitchen workers calling in sick!

POOR COMFORT CONDITIONS AND HIGHER ENERGY BILLS

When your restaurant lacks replacement air, your heating and cooling conditions will be unbalanced. Often the measures taken to mediate that unbalance can make matters worse. And increase your utility bills!

What Is the Difference Between a Type 1 and Type 2 Hood?

Type 1 and Type 2 Hoods

Hoods that are designed to capture and hold grease are called “Type I” hoods. Type 1 hoods are for use over equipment such as griddles, fryers, broilers, ovens, ranges, and wok ranges. These hoods are required to use a UL300 Wet Chemical Fire Suppression System.

Hoods that are designed to remove steam or heat are called “Type II” hoods and are designed for use over equipment such as steamers, kettles and pasta cookers.

When any cooking appliance under a single hood requires a Type I hood, a Type I hood must be installed. Where a Type II hood is sufficient, either a Type I or Type II hood may be installed.

(NOTE: UL does not currently certify type II hoods)

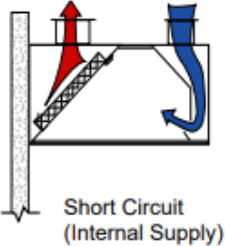

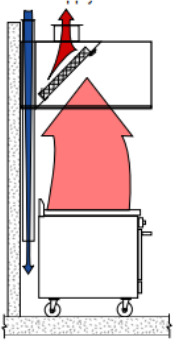

Short Cycle Makeup Air Hoods

Short Cycle or internal compensating design directs the air into the front inside of the hood.

The Short Cycle baffles the air up to 80%, which has the following benefits:

Lower Up Front Cost: No purchase of costly tempered unit

Lower Energy Bills: No costly heating bills to run a tempered make-up air unit

Lower Installation Cost: Easier installation

Short Cycle Design with internally compensating air does not change the ambient room temperature

Maintains comfort in the kitchen and for the staff

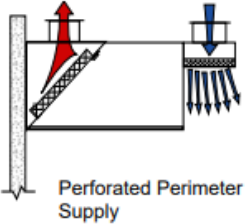

PSP (Perforated Supply Plenum) Makeup Air Hoods

Perforated Supply Plenum design directs the MUA downward into the capture area of the hood.

The MUA is introduced downward on the outside front of the hood above where the cook stands and cause discomfort.

When using the Perforated Supply Plenum design in most applications, conditioned air is required.

Hot in Summer

Higher Energy Bills

Back Return Plenum

The Back Return Plenum design can be an effective way to introduce MUA.

Discharge area of the backwall MUA should be at least 12” below the cooking surface to prevent interference with gas burners and pilot lights.

Another benefit of the Back Return may be the advantage of meeting a “clearance to combustible” code requirement.

Makeup Air Hoods UL vs. ETL

HoodMart hoods are all UL 710 listed. Most competitors are ETL Listed to the UL 710 Standard.

UL creates the standard, while ETL is a third party that only tests to the UL standards

UL is used by companies that are working to innovate and create new products that are mechanically and electrically safe

When installing UL Equipment, you can be assured that UL recognized components (fans, contactors, switches) are designed and tested to be used together to meet the UL standards

Makeup Air Hoods UL710 Features & Benefits

HoodMart offers the first UL 710 Listed hood that is not required to have duct connections cut at the factory

Allows for easier installation because site conditions may vary

Non-Insulated zero clearance front.

Allows front of hood to go directly against a drywall ceiling and reduces hood weight for easier and faster installation.

Lowest CFM/FT for listed hood over 700 degree appliance (UL or ETL).

Significantly reduces operating cost.

Non-bolted or gasketed construction (fully welded).

Allows for long term stability.

All hoods include side curtains.

Lowers energy cost and provides better fire containment.

20” high Filters with integrated ridges

20” height allows grease laden air to be pulled in more quickly.

Constructed of 18 gauge Stainless Steel

430 Stainless with a #3 Polished finish

Listings include UL710, Built to NFPA Standard, NSF Marked

ALL HOODS ARE MADE IN USA

Makeup Air Hoods Packages

Hood Makeup Air Packages include:

Exhaust Fan

Hinge Kit

Makeup Air Fan (Fresh or Tempered available)

Vapor-proof Lights, Grease Cups & Filters

Roof Curbs

UL 710, NFPA96, NSF

Fire Suppression System (optional)

Single or double wall ductwork (optional)

CUSTOM FABRICATOR

CUSTOM FABRICATOR